| |

|

|

| |

|

|

| |

|

|

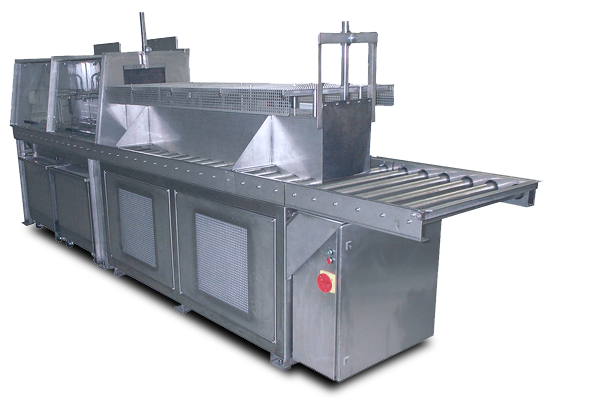

Washing & Drying Unit [WDU]

The Washing and Drying unit has been designed for the washing and drying of glass, quartz or ceramic tubes for the removal of the sawing sludge and any additional dirt which was present on the Tube prior to the Cutting Process.

- Most effective system for Washing & Drying Tubes

and Rods in High Volume

- Can be used as stand alone equipment

- Easy to operate with low maintenance

|

|

|

|

|

|

| |

|

|

| |

|

|

| |

Washing entrance through slide door, on PVC Coated Stainless Steel Rollers. Pre washing by top and bottom high volume water spraying. Basket will exit first station over Conveyor Roller and transported to the Ultrasone Warm Station. The operator will manually place the basket in the Ultrasone Unit where it will sit for 3 minutes. After 3 minutes the operator will rinse the products in warm Osmoses water.

Once the products are rinsed the operator will place the basket in the Drying Unit. Drying entrance through 2nd door. Drying by blow of and hot air principle. The whole 2 meter section of drying is thermal insulated. Desired throughput can be set at 15, 30, 45 and 60 min. Different time range is also possible. The unit includes a complete stand alone water treatment unit (osmoses). The Osmoses water preparation unit comes with:

- work tank of 200 l. including level switches pumps and flow control.

- water softener (ion exchanger) to pre work the water for the osmoses unit.

- Regenerator for the ion exchanger.

|

|

| |

| Control Unit: |

Allen Bradley PLC

with IO connection possibility for in line equipment |

| Air Connection: |

1/4" pipe, 6 bar |

| Water Consumption: |

adjustable up to 300 ltr per hour.

Osmoses unit produces this water with a loss of 25% depending on water temperature |

| Power Supply: |

Standard 400V - 50Hz - 40kW - 3p +n +pe |

|

|

|

| |

|

|

| |

The heavy and rigid frame structure and the unique roller construction results in a very maintenance free reliable piece of equipment. For ease of maintenance and rust prevention, stainless steel is used for almost all Parts. This equipment has been designed for around the clock operations. |

|

| |

|

|